Behind the Design – Metal Fabrication

Behind the Design – Metal Fabrication

Behind the Design- Metal Fabrication

Have you ever wondered how metal is formed, shaped, and treated to make your brand, product or structure come to life? The all-encompassing definition for this is called metal fabrication. It is the process of manufacturing and manipulating metal by forging, casting, drawing, forming, machining, extrusion, cutting, punching, stamping, and welding the metal to your desired outcome. With the help of machinery and highly skilled fabricators, metal can be molded into almost anything.

Metal is a highly preferred material due to its quality and durability. Because of this, it’s commonly used for foundational support: from entire structural environments to the smallest of accessories to enhance stability, customization, and strength. Using metal also promotes sustainability because leftover metal can be recycled and reused. On average, SEG Systems recycles 3,450 pounds of aluminum per month!

“Our selling point is giving the customer what they want. We give what other competitors can’t make or wouldn’t want to take on. With our metal fabrication, it’s all about our custom solutions.”

-Bill Pickens, SEG Systems Lead Fabricator

Pickens has been working in the metal fabrication industry for 45 years, with a background in defense vehicles along with automotive prototyping and racing.

Since Pickens started his metal fabrication career, the manufacturing industry has shifted from being built by hand to being built by machines. Today, almost every manufacturing department depends on machinery to get a job done accurately and on time. “Metal fabrication uses CAD drawings and laser machines to make their process easier, but the custom jobs are still being hand-crafted,” says Pickens. “We get the chance to be more involved with the product because of the meticulous, hands-on steps like drilling, bending, welding, and making custom brackets.”

Custom Metal Fabrication

Fresh Market Cart Display

“In less than three weeks, we built 200 wheels and axels for Fresh Market carts, all made from scratch. This job was complicated because it was a lot to build in a very short amount of time,” says Bill Pickens. To create perfectly round and functioning wheels, the metal was cut, formed, machined, and welded by our fabricators’ hands.

Nike Shoe Merchandisers

Merchandiser displays don’t have to be boring. These z-frame pedestals include a lightbox that serves as a product glorifier and signage.

Custom 3D signage for Fanimation

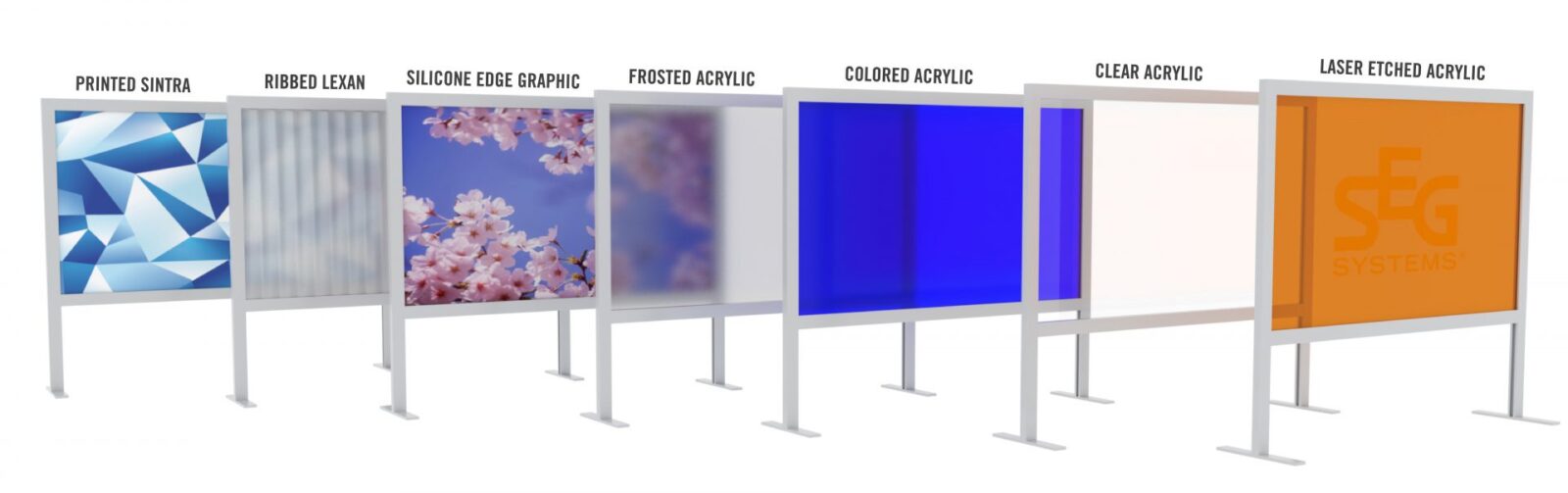

These HDU foam letters were brushed with an aluminum laminate face, which offers an upscale look without the cost of solid metal letters. The visual appeal of a display can be enhanced by adding one of our 1000+ powder coated colors and finishes including brushed gold, polished gold, brushed silver, polished silver, and brushed copper. Adding this extra layer also improves durability and strength.

Polar pop tubular drink display for Circle K

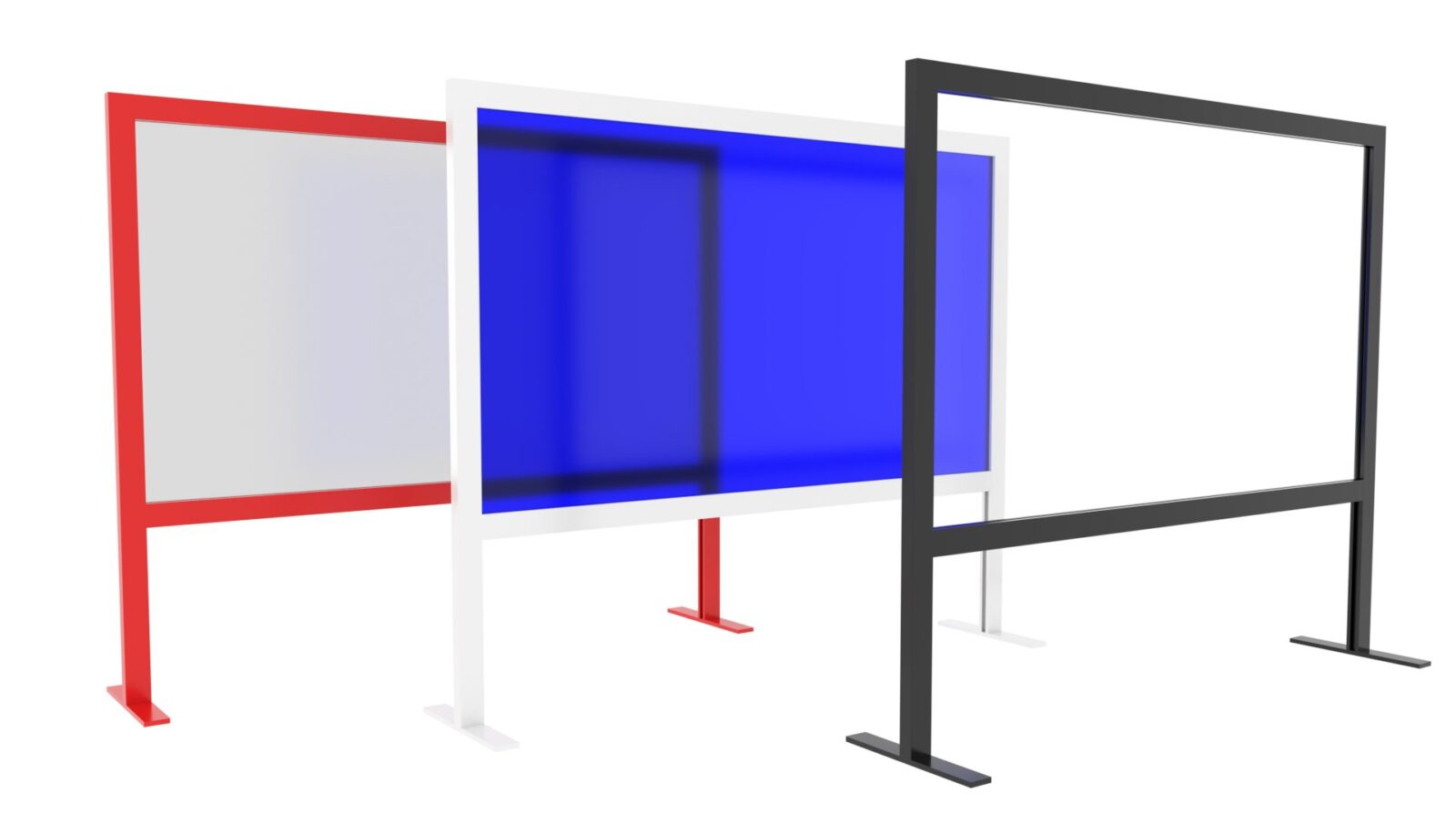

Displays can be molded into a variety of shapes with the forming process, which is accomplished when metal is bent with pressure to create a curved or angled product. Whether it’s a suspended frame or a freestanding frame, metal can be shaped into a tubular, trigon, prism, cube, or custom shaped display.

Under Armour Dunk House

This entirely custom, metal structure was constructed as a traveling pop-up at Under Armour activations and professional sporting events nationwide. The display was carefully designed to withstand thousands of active attendees while also being modular and lightweight to travel from event to event.

Hanes runway tubular suspended frame

This tubular, suspended frame was built to maintain the structure’s shape when hoisted above the runway. Using a metal frame provided a light-weight solution that ensured the cables would support the structure as it’s suspended from the ceiling.

Why SEG Systems?

SEG System’s metal fabrication is unique because of our solution-based mindset. As metal fabrication has changed over time, our metal fabricators have adapted by acquiring both hands-on and machine-based skills, with over 60+ combined years of experience. With a range of perspectives and skills, SEG Systems has gained the manpower to fulfill both quick orders and complex orders.

View more of our Metal Fabrication projects:

Nike custom metal fabricated, and powder coated riser base

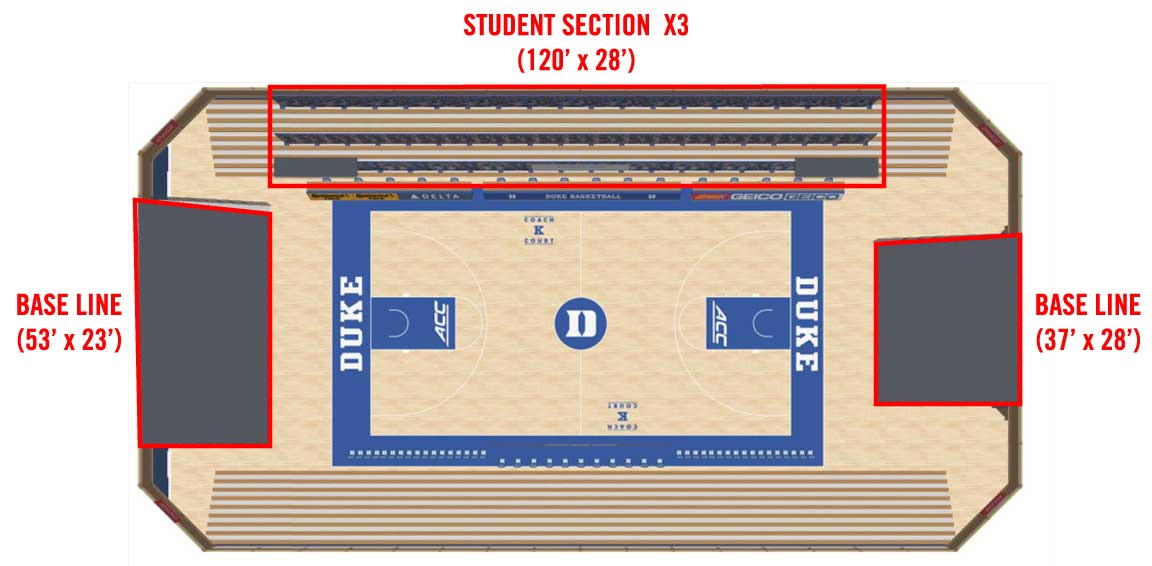

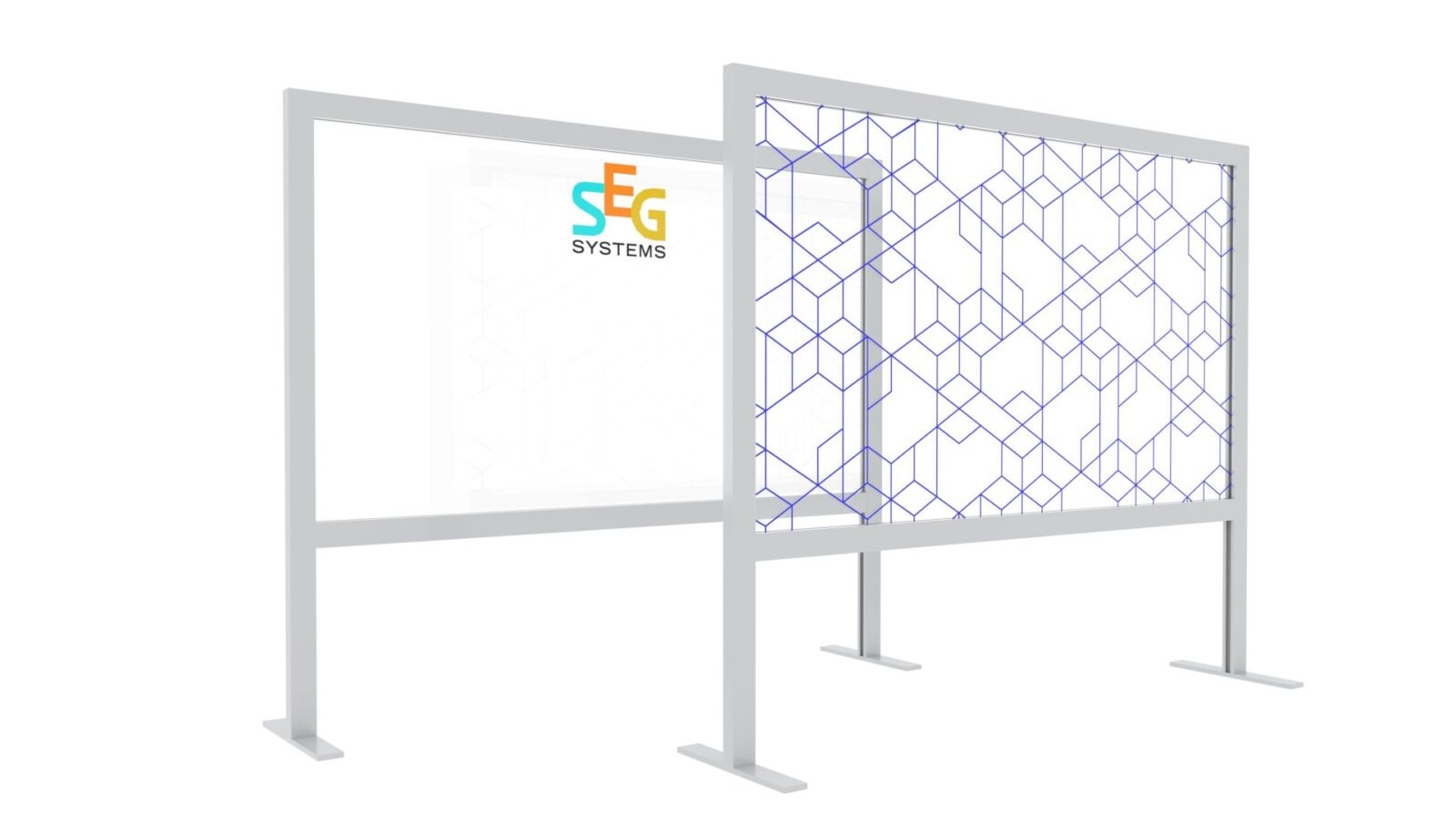

Syracuse University backlit signage with colored graphic

Collapsible counters for Under Armour

Caged Product glorifiers integrated with lighting and acrylic

We would love to work with you! Check out our FAQs or Contact Us today to get started.

Behind the Design- Metal Fabrication

Have you ever wondered how metal is formed, shaped, and treated to make your brand, product or structure come to life? The all-encompassing definition for this is called metal fabrication. It is the process of manufacturing and manipulating metal by forging, casting, drawing, forming, machining, extrusion, cutting, punching, stamping, and welding the metal to your desired outcome. With the help of machinery and highly skilled fabricators, metal can be molded into almost anything.

Metal is a highly preferred material due to its quality and durability. Because of this, it’s commonly used for foundational support: from entire structural environments to the smallest of accessories to enhance stability, customization, and strength. Using metal also promotes sustainability because leftover metal can be recycled and reused. On average, SEG Systems recycles 3,450 pounds of aluminum per month!

“Our selling point is giving the customer what they want. We give what other competitors can’t make or wouldn’t want to take on. With our metal fabrication, it’s all about our custom solutions.”

-Bill Pickens, SEG Systems Lead Fabricator

Pickens has been working in the metal fabrication industry for 45 years, with a background in defense vehicles along with automotive prototyping and racing.

Since Pickens started his metal fabrication career, the manufacturing industry has shifted from being built by hand to being built by machines. Today, almost every manufacturing department depends on machinery to get a job done accurately and on time. “Metal fabrication uses CAD drawings and laser machines to make their process easier, but the custom jobs are still being hand-crafted,” says Pickens. “We get the chance to be more involved with the product because of the meticulous, hands-on steps like drilling, bending, welding, and making custom brackets.”

Custom Metal Fabrication

Fresh Market Cart Display

“In less than three weeks, we built 200 wheels and axels for Fresh Market carts, all made from scratch. This job was complicated because it was a lot to build in a very short amount of time,” says Bill Pickens. To create perfectly round and functioning wheels, the metal was cut, formed, machined, and welded by our fabricators’ hands.

Nike Shoe Merchandisers

Merchandiser displays don’t have to be boring. These z-frame pedestals include a lightbox that serves as a product glorifier and signage.

Custom 3D signage for Fanimation

These HDU foam letters were brushed with an aluminum laminate face, which offers an upscale look without the cost of solid metal letters. The visual appeal of a display can be enhanced by adding one of our 1000+ powder coated colors and finishes including brushed gold, polished gold, brushed silver, polished silver, and brushed copper. Adding this extra layer also improves durability and strength.

Polar pop tubular drink display for Circle K

Displays can be molded into a variety of shapes with the forming process, which is accomplished when metal is bent with pressure to create a curved or angled product. Whether it’s a suspended frame or a freestanding frame, metal can be shaped into a tubular, trigon, prism, cube, or custom shaped display.

Under Armour Dunk House

This entirely custom, metal structure was constructed as a traveling pop-up at Under Armour activations and professional sporting events nationwide. The display was carefully designed to withstand thousands of active attendees while also being modular and lightweight to travel from event to event.

Hanes runway tubular suspended frame

This tubular, suspended frame was built to maintain the structure’s shape when hoisted above the runway. Using a metal frame provided a light-weight solution that ensured the cables would support the structure as it’s suspended from the ceiling.

Why SEG Systems?

SEG System’s metal fabrication is unique because of our solution-based mindset. As metal fabrication has changed over time, our metal fabricators have adapted by acquiring both hands-on and machine-based skills, with over 60+ combined years of experience. With a range of perspectives and skills, SEG Systems has gained the manpower to fulfill both quick orders and complex orders.

View more of our Metal Fabrication projects:

Syracuse University backlit signage with colored graphic

We would love to work with you! Check out our FAQs or Contact Us today to get started.