About Us

The SEG Difference Mission Goal Motto

Since that time, SEG has built their reputation on having a solution for any scale project. They have committed to investing in the latest technology, specialized equipment, tooling, creative lighting solutions, and growing our capabilities beyond SEG frames, fixtures, and lighting but also to include millwork, steel fabrication, acrylic, and finishing techniques.

The greatest asset SEG has is our people. Every employee and puppy at SEG Systems are family and we aim for our customers to feel that same sense of inclusion.

Capabilities

Custom Fixtures & Displays

Your project is one-of-a-kind, and we’re here for that. We have a select few “stock” fixtures, but they’re all built to order and built just for you! Need to tweak the design? Want to start from scratch? Start with SEG Systems

Metal Fabrication

To create one-of-a-kind SEG structures, SEG fixtures, and SEG lightbox accessories, SEG Systems uses their custom metal fabrication capabilities to plasma cut, weld, and grind aluminum and steel.

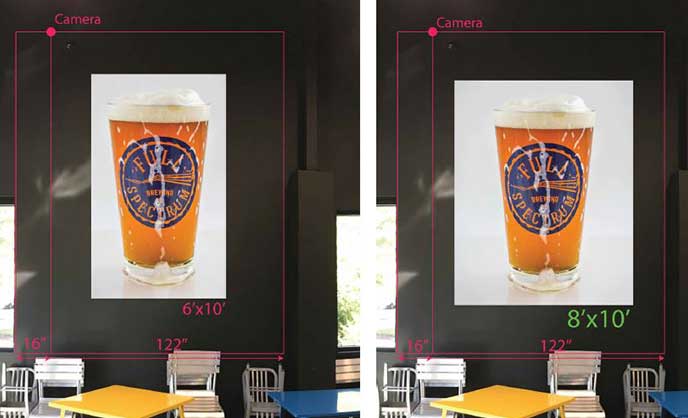

19 Lighting Solutions

There are several factors that determine what type of lighting to use for the most optimal SEG lightboxes. Take a gander and see what lighting solution would best fit for your environment.

CNC Machining

SEG Systems converts CAD models into reality using our CR Onsrud CNC machine. This machine allows for percision cutting for a wide range of materials including plastic, wood, foam, and composites.

Acrylic

Acrylic comes in many shapes and sizes – and at SEG Systems, that includes laser etching and engraving. Need a simple display case? Need a laser-etched pedestal to highlight your products? We’ve got your back. Or your Acrylic.

Millwork

Count on SEG Systems to create a millwork piece to integrate with the latest technology to create cabinetry, mannequin bases, and custom displays for your brand’s new look.

92 Extrusions Available

With 92 extrusions available, we’re sure to have one that will work for you. If not, we’ll make one custom for your needs.

Metal Bending

Think outside of the box. SEG fabric frames and SEG lightboxes don’t have to be square. We offer metal bending in order to create the perfect frame for your standards.

1,000+ Powder Coat Colors & Finishes

Pick a color, any color. We PMS match our powder coat so that no part of your display strays from your brand’s standards using our in-house paint booth.

Printing

SEG Systems uses the latest printing technology and is able to print on fabrics, rigid materials and acoustic P.E.T felt. Our G7 certification ensures the production of the highest quality, consistent, and accurate color graphics.

Services

Site Survey

Designing a new space for your brand can be daunting. Need an extra set of eyes to make the visiona little bit more clear? Let’s meet up. We love brainstorming.

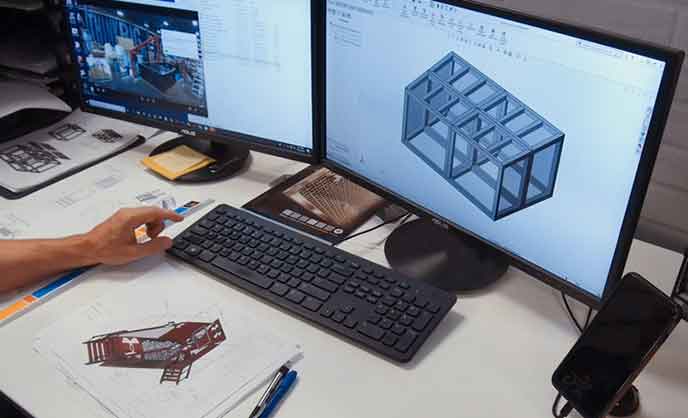

Engineering

The engineers at SEG Systems ensure that every design is going to turn out seamlessly. No idea is too wild for these guys. Hit’em with your best shot!

Custom 3D Renderings

After finalizing the details of your project, SEG Systems will create renderings that bring your brand to life.

Graphic Design

The Graphics team at SEG ensures that every image or piece of text you send over for your silicone edge graphic is ready for print and will fit perfectly into your frame.

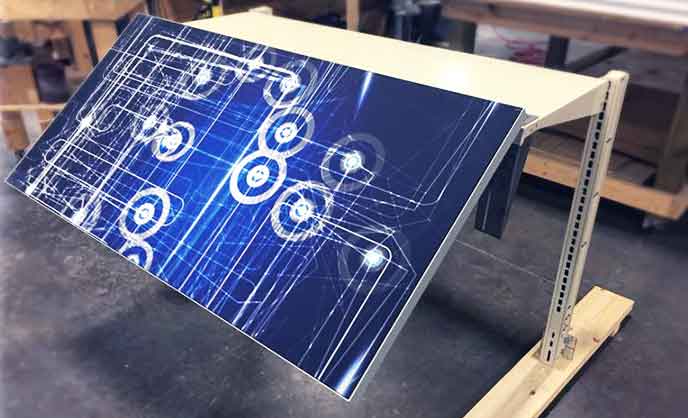

Prototyping

Our Product Development team is constantly manufacturing and testing products in order to achieve a perfect prototype from which a complete system or product can be developed.

Project Management

Once your project goes into production, you’ll be assigned a Project Manager. This person will be there for you and your company through the entire process and jump any hurdles along the way.

Quality Control

At SEG Systems, we take every possible step to ensure your project is perfect. Before your project ships out, it goes through a rigorous quality control process that includes assembly, power testing, and graphic fitting!

Custom Crates & Packaging

SEG Systems designs and builds custom crates and packaging to ensure that your project will arrive as perfect as it gets shipped out.

Onsite Install

Most of SEG Systems’ aluminum SEG frames are easily installed at an associate level, but if you need extra help, we’re here for you. Just ask your Project Manager!

The People have Spoken

"Thank you so much for working hard to get the fixtures and graphics here in time. They were such a huge hit!"

Centerplate

"Understanding the speed of retail, UL has developed this innovative program to meet the tight timeframes of manufacturers while simultaneously leveraging the same rigorous testing and certification standards to which we are committed to ensure the safety of commercial displays. We applaud SEG Systems on their commitment to delivering safe frames and displays to retail"

UL

"Thank you for always being available and making things "work". It is so great to work with a sales rep that is on top of his game at all times and helps you get out of trouble even in a time crunch."

Britten Inc.

“Dealing with resolution issues is a large part of our business. I’m glad to see SEG Systems stays on top of such things and helps us work them out. It sets your company apart.”

Creative Surfaces Inc.

“SEG graphics are a great solution for large format printing, with a high-end look and easy changeability. We utilize SEG in some form on almost every project that we design, and when we’re producing SEG graphics, we’re using SEG Systems.”

Jack Porter Inc.

“We installed one of your SEG wall mounted frames in our plant atrium area as a sample for our customers to view and are thrilled with the brightness and quality.”

Lithographix, Inc.

“SEG Systems has amazing quality and amazing customer service! My account representative is always available and gets me the answers I need very quickly…even at midnight. They will make your vision a reality and do it with a smile. Our client’s were beaming with joy when they saw the final product and it was the talk ofthe event!”

Multi Image Group

"Our install went off without a hitch and wanted to send you all a big THANK YOU for making this happen!!! I can’t tell you how happy our client was that this made it and installed prior to opening. Ya’ll are the best team ever!"

Agency

"I was very pleasantly surprised with the level of detail and quality from SEG Systems frames we purchased. I have been wanting to work on this project for some time now and with other companies hit roadblocks, we can do this but not that part or we can do this, but not that. The team at SEG Systems took what I was looking for, said ‘we can do it all for you,’ and they delivered with outstanding results. It is nice to work with a team that can get done what your client wants without putting up roadblocks."

Brede Exposition Services

"SEG Systems has been a great partner for RRD! They came in with the knowledge and the TEAM attitude that allowed us to work together to promote that growth and new opportunities. They've added a great value to our product offerings and really took the time to understand our business and goals."

R. R. Donnelley

"I wanted to thank you for you and your team’s thoughtfulness and attention to detail on the Urban League project. You sent us great instructions, well crafted crates, extremely useful hardware, and perfectly sized (and extra!!) graphics to create a great install experience for the cabanas on site. I am very appreciative! Please express my gratitude to your team, too, for making this happen for us on such a compressed timeline and doing it with such grace and attention. Thank you!"

Agency

“We were so happy to partner with SEG Systems on our special project for Duke Basketball. They think like we do; anything is possible! No one could have imagined Cameron Indoor Stadium without ‘The Cameron Crazies’! We all have had to adjust our way of thinking and messaging in 2020. SEG is a fantastic partner.”

#zebradog, #therealzebradog

Zebradog: Dynamic Environment Designs

"SEG is defined by innovation, creative problem-solving and candid communication. It’s running through the veins of everyone I’ve met there. I’d call that inspiring also."

PetSmart

"You all just don't F around. I love it. And appreciate it."

Creative Retail Production

“The client and my team are very happy. SEG Systems does top-quality workmanship!”

Steel City Displays

The People have Spoken

"SEG is defined by innovation, creative problem-solving and candid communication.

It’s running through the veins of everyone I’ve met there. I’d call that inspiring also."

PetSmart

"Thank you so much for working hard to get the fixtures and graphics here in time. They were such a huge hit!"

Centerplate

"Understanding the speed of retail, UL has developed this innovative program to meet the tight timeframes of manufacturers while simultaneously leveraging the same rigorous testing and certification standards to which we are committed to ensure the safety of commercial displays. We applaud SEG Systems on their commitment to delivering safe frames and displays to retail"

UL

"Thank you for always being available and making things "work". It is so great to work with a sales rep that is on top of his game at all times and helps you get out of trouble even in a time crunch."

Britten Inc.

“Dealing with resolution issues is a large part of our business. I’m glad to see SEG Systems stays on top of such things and helps us work them out. It sets your company apart.”

Creative Surfaces Inc.

“SEG graphics are a great solution for large format printing, with a high-end look and easy changeability. We utilize SEG in some form on almost every project that we design, and when we’re producing SEG graphics, we’re using SEG Systems.”

Jack Porter Inc.

“We installed one of your SEG wall mounted frames in our plant atrium area as a sample for our customers to view and are thrilled with the brightness and quality.”

Lithographix, Inc.

“SEG Systems has amazing quality and amazing customer service! My account representative is always available and gets me the answers I need very quickly…even at midnight. They will make your vision a reality and do it with a smile. Our client’s were beaming with joy when they saw the final product and it was the talk ofthe event!”

Multi Image Group

"Our install went off without a hitch and wanted to send you all a big THANK YOU for making this happen!!! I can’t tell you how happy our client was that this made it and installed prior to opening. Ya’ll are the best team ever!"

Agency

"I was very pleasantly surprised with the level of detail and quality from SEG Systems frames we purchased. I have been wanting to work on this project for some time now and with other companies hit roadblocks, we can do this but not that part or we can do this, but not that. The team at SEG Systems took what I was looking for, said ‘we can do it all for you,’ and they delivered with outstanding results. It is nice to work with a team that can get done what your client wants without putting up roadblocks."

Brede Exposition Services

"SEG Systems has been a great partner for RRD! They came in with the knowledge and the TEAM attitude that allowed us to work together to promote that growth and new opportunities. They've added a great value to our product offerings and really took the time to understand our business and goals."

R. R. Donnelley

"I wanted to thank you for you and your team’s thoughtfulness and attention to detail on the Urban League project. You sent us great instructions, well crafted crates, extremely useful hardware, and perfectly sized (and extra!!) graphics to create a great install experience for the cabanas on site. I am very appreciative! Please express my gratitude to your team, too, for making this happen for us on such a compressed timeline and doing it with such grace and attention. Thank you!"

Agency

“We were so happy to partner with SEG Systems on our special project for Duke Basketball. They think like we do; anything is possible! No one could have imagined Cameron Indoor Stadium without ‘The Cameron Crazies’! We all have had to adjust our way of thinking and messaging in 2020. SEG is a fantastic partner.”

#zebradog, #therealzebradog

Zebradog: Dynamic Environment Designs

“You all just don’t F around. I love it. And appreciate it.”

Creative Retail Production

“The client and my team are very happy. SEG Systems does top quality workmanship!”

Steel City Displays

Get to Know SEG Systems Better

Meet the Team

Learn our Process